Therefore this document does not cover turret structures or I-tubes and J-tubes for example. The test regime is chosen to demonstrate that a particular design or design feature is suitable to withstand the repeated flexures sustained by an umbilical during manufacture transfer spooling load-out I- or J-tube pull-in burial and for a dynamic.

Flexcom 8 J Tube Pull In Youtube

This specification does not cover flexible pipe and umbilical ancillary equipment beyond the connector with the exception of riser bases and load-transfer devices.

. Flexlife was approached to design fabricate and supply a riser system which included a flexible pipe J-tube and associated clamps for an existing field tieback in the East Irish Sea. Oceaneering tube seals are suitable for use with I and J tubes and are fitted to umbilicals to protect customers assets. Therefore this document does not cover turret structures or I-tubes and J-tubes for example.

This RP does not cover ancillary equipment for flexible pipes and umbilicals beyond the connector with the exception of riser bases and load-transfer devices. Diverless Bend Stiffener Connectors for Flexible Pipe Risers. J-tube seals are used to provide sealing and corrosion protection between flexible umbilicals cables or pipes and the so-called J- or I-tubes found on offshore installations in the oil gas and renewable energy sectors.

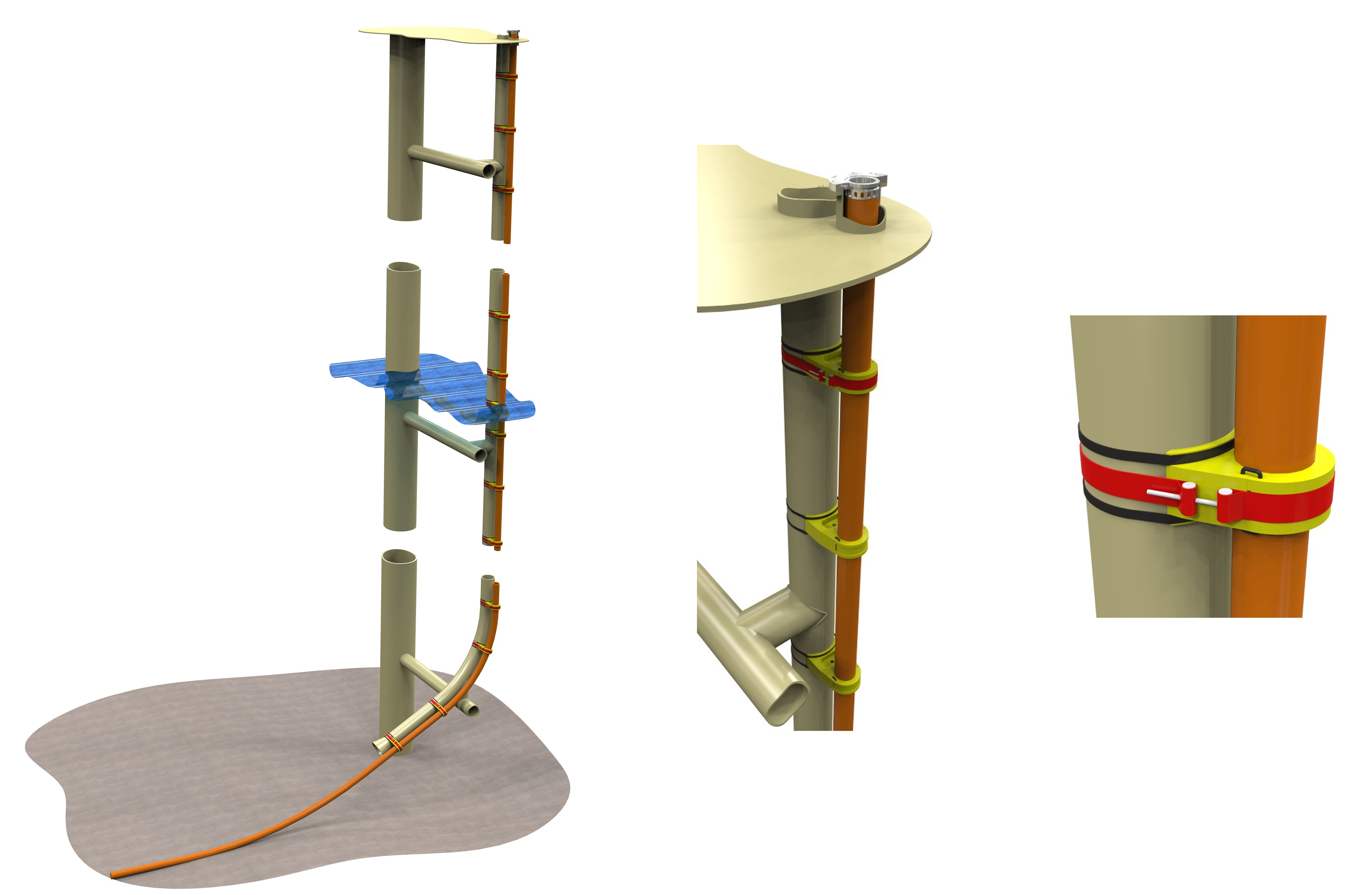

J- tube seal is used to seal the interface between the umbilicalcable and the inside of a J-Tube incorporating a watertight seal in which an anti-corrosion inhibitor is. To those not involved in the engineering and design of umbilicals these opposing characteristics can appear confusing. J-Tube Seals are used to seal the interface between the inside of a J-Tube and the riser and can be designed for diver and diver-less installation.

Diverless Bend Stiffener Connectors BSCs for Risers The Bend Stiffener Connector BSC is a field-proven system to facilitate diverless connection of Umbilical and Flow line bend stiffeners to an I-tube or J-tube. Subsea Umbilicals Risers Flowline Protection Solutions SURF. This recommended practice provides guidelines for the design materials selection analysis testing manufacture handling transportation installation and integrity management of ancillary equipment for flexible pipes and umbilicals.

The basis for assessment of fatigue damage of such elements is the long-term stress cycle distribution at critical locations on the helix elements caused by long-term environmental loading on the system. It is designed for the most extreme conditions in terms of depth temperature and pressure. This has increased the opportunity for flexible pipe pull-in beyond the traditional J-tube.

J-tubes experience both pull-in and pull-out loads in practice and the latter. Flexible tooling design allows BMPs ProShell. Over 100 Bend Stiffener Connectors have been supplied.

It may even become the critical path depending on market conditions for tubes cables bundling etc. This document does not cover ancillary equipment for flexible pipes and umbilicals beyond the connector with the exception of riser bases and load-transfer devices. It presents the current best practice for design and procurement of ancillary equipment and gives guidance on the implementation of the.

A hyper-duplex stainless steel developed for deepwater umbilicals. Manufacturing of Steel Tube Umbilicals. The design of a dynamic umbilical is an iterative process and is time consuming.

The radius of the J is a function of whether the risers to be pulled up the J tube are flexible or more normally rigid pipe- on the platform Im on. This document does not cover ancillary equipment for flexible pipes and umbilicals beyond the connector with the exception of riser bases and load-transfer devices. SAF 3207 HD offers greater yield strength greater corrosion resistance and superior fatigue properties compared to super-duplex.

Fatigue analysis of helix elements such as tensile armors and steel tubes are critical design issues for dynamic umbilicals and flexible pipes. The seals enable clients to dose anti-corrosion andor biocide chemicals into the. This has allowed flexible pipe to be pulled up a J-tube originally intended for umbilicals.

Study it was found that flexible pipe could be pulled up a spare conduit that had bends totalling to more titan 360 degrees along its length. The design of J-tubes with one or more bends under functional loads is dictated by a single force T L the cable tension at the bottom of the J-tube. A tube shaped like a J extending from the top of a jacket to the mudline or close to the mudline with a bell mouth on the end to provide a conduit to pull risers up.

Therefore this document does not cover turret structures or I-tubes and J-tubes for example. Therefore this document does not cover turret structures or I-tubes and J-tubes for example. 425 valid for tube and pipe.

Steel tubes are relatively stiff and of high tensile strength. The following graphic illustrates the iterative nature of umbilical design. Design Minimum length of 5 ft 15 m is required between the pulling head and hang off collar location if required Termination of strength member Naturally aligning pyramid stab and hinge design Split hang off plate Suit flange located at the top of the I TubeJ Tube hardware included as required Thermoplastic hose and steel tube couplings.

Balmoral provides diverless and diver-installed seals that are available in a range of sizes for pre- or retrofitting. The field is extensively faulted and consists of two main accumulations. In addition this document does not cover storage devices such as reels for example.

5 depicts a tensile armour wire rupture of a flexible pipe caused by abrasion. The Don field is situated in Block 2ll18a about 15 km north of BPs Thistle Platform and is in 170 meters water depth. We offer seals to suit all tube sizes and umbilical diameters.

In addition it does not cover flexible pipe or umbilical storage devices for example reels. This facilitates the analysis of J-tubes using standard beam theory or for complex shapes a simple computer model. Ennsub Subsea J-Tube Installation.

An overall computational consistent and efficient fatigue analysis scheme is outlined with due regard of the cross-sectional analysis technique required for fatigue stress calculation with particular attention to the helix elements. Design of subsea cablesumbilicals for in-service abrasion - Part 1. A J tube is exactly that.

The design had to take into account shallow water dynamic field infrastructure ageing assets a lack of survey data and restricted topside access. Thermoplastic hoses are relatively flexible and of low tensile strength. Fatigue analysis of structural components such as helix tensile armors and steel tubes is a critical design issue for dynamic.

Subsea Distribution Products Oceaneering

Flexible Riser Riser Pipe Design And Specification Flexlife

Retrofit J Tube For Offshore Installation Gce Ocean Technology

0 komentar

Posting Komentar