It is accomplished by dragging the gun along the weld seam at the proper rate to allow fusion to occur. Vertical welding is easier when the base metal is at 45 and harder at 90.

Vertical Up Settings Help Mig Welding Forum

Cross country pipe lines often use down hand.

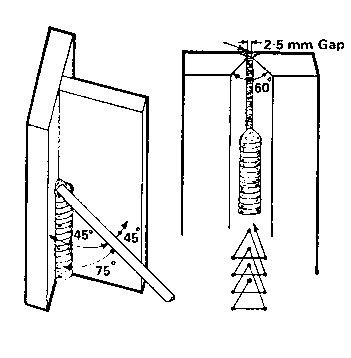

. Weaving is a side to side motion. Circles are a circular or oval motion. The MIG gun handle should be pointed up between 35 to 45 degrees.

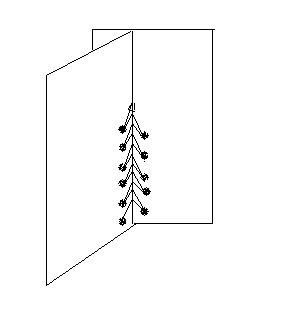

If I have an L shaped area to weld with one of the two sides being vertical I will run a J type pattern ware I creat a ramp with each stroke to run up and hold it aginst the vertical piece. The figure eight and zigzag weaving motion is a good technique for making a cover pass when you are in the vertical welding position of flat welding position. The 3 patterns that work the best are.

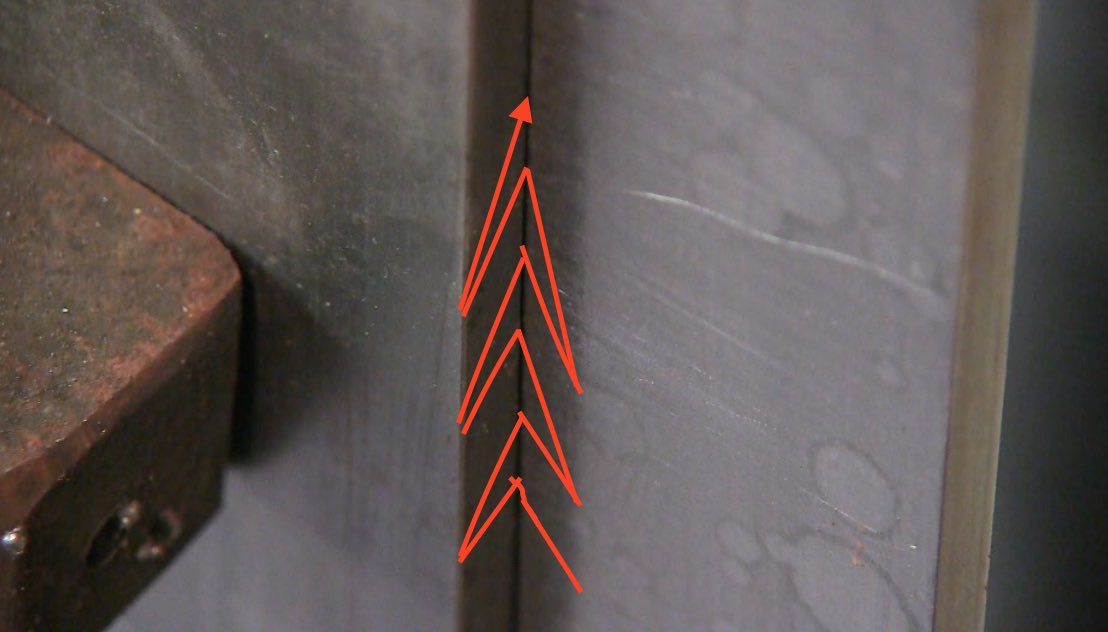

Sure there are other ways of making a good looking vertical uphill weld but for ensuring penetration as well as making a good looking uniform weld the upside down V is a very good way to go. The upside down V is one of the most effective techniques for vertical mig welding of lap and tee fillet welds. Most of the MIG welders dont like to weave or use any welding beads pattern.

Forehand vs Back-Hand. Thus you will need to take certain considerations such as a reduction in amperage of your machine at first because the hotter the puddle the more easily it will drop to the ground. You might need a pre-weld setup ready to make sure your vertical welding can be done efficiently and with ease.

In vertical welding the axis of the metal weld is always vertical in position. The best welders are quite fussy about surface preparation and cleaning the base metal is a good habit to get into. Hold the MIG gun at a 90-degree angle to each piece of metal when welding a butt joint to direct the heat and filler metal equally to each piece of material.

Vertical welding position requires you to work against the force of gravity. Vertical Up MIG Welding Technique. Working uphill the welder can use a variety of patterns to spread the filler metal into the joint.

Use the right wire. The straight line bead you refer to is called a stringer bead. Vertical welding needs concentration and stability.

This pattern greats a flat stack of dimes. There are ways to weld vertical down and it takes time to learn. Again as we go against gravity it is better to reduce the voltage and amperage to about 10-15 of its initial values.

10 Techniques To Practice. When it comes to vertical welding doing both up and downward will be hard. The chart below includes all 8 techniques above plus two more the V and the upside down V which can be used uphill.

05-02-2012 0458 PM. If you insist on running hard wire on vertical up then. It may look good but itmay not be fused.

When it comes to the MIG welding position one of the most difficult techniques is the vertical up position as you need to have the MIG gun pointed upwards at an angle of 35-45 degrees. The whip a back and forth motion. Your settings should be hot enough to penetrate without sending the filler running down the joint.

This can result in lack of fusionbetween welds. You need to be able to control your travel speed so that you can pump enough metal into the joint. Weaves are much easier on vertical tests but sometimes CWIs will only allow stringer passes.

The characteristic appearance is a smooth ripple-free bead with a rounded appearance. MIG welding is more tolerant of minor surface contaminants than TIG welding but the cleaner the metal the fewer problems youll have. Vertical Up MIG Welding Techniques.

Thick pipe at least sch. This pattern makes a nice contour to the weld with the end result looking like butterfly wings. Ensure you dont have any equipment nearby because welding spatter can damage or permanently scar most surfaces.

So if you want to practice its best to start at 45. Like weaving there is a separate forehand and backhand method for each pattern. Mig Welding Patterns images similar and related articles aggregated throughout the Internet.

If we point that flame given to it at an angle of 45 degrees the rapid flow of the molten weld can be stopped and controlled too. Stringers are used mostly on thin stock or on thick stock where you plan multiple passes. If you need help with welding vertical up it always a.

The vertical up weld in MIG is typically very convex. MIG was the only process we didnt do vertical in maybe for good reason but we did vertical OFW SMAW and TIG. When you should not weave for MIG welding you have three other options.

Shows how to make Vertical fillet and prepared butt welds and Overhead fillet and prepared butt welds with a MIG Welder. If your having to weld vertical up with mig and your welding anything thicker then 14 material run a dual shield wire e71t and not only will the weld appearance be much bettar but you can easily weld vertical up and not have the puddle fall out. They will completely create an upright bead with the aid of a stinger.

Vertical up is the most difficult of the MIG welding positions. Butt weld a 180-degree joint. Generally when we tend to do vertical welding the molten weld flows downwards due to gravity and gets piled up.

The problem with vertical down is the weld can overlap. A vertical weld can be performed in. Those options are comprised of the circle holding still and whipping.

I welded up some new spring and shackle perches on our 49 Jeep Willys frame yesterday and I knew from welding school that welding vertical was going to be different we didnt do vertical MIG welding at schoo. Once you have that down you are ready to weld. If you have to chase your weld downhill youre not getting the right penetration you need for your weld.

Vertical MIG welding is one of the most difficult and tiring welding position to master. When welding vertical up you need to build a shelf of weld to work upward on. And during vertical up GMAW welding the welder needs to create a weld shield to move upwards.

MIG welding is very easy to learn but since it is a semi-automatic process much of the skill relies on machine set-up. Whipping is distinctly different from weaving and the circle pattern technique is a combination of the two. Demonstrates MIG welding techniques.

When Vertical MIG Welding Goes Wrong. 80 is usedthe sch40 can be used but not always. 04-15-2012 1111 AM.

Hold the gun at a 90-degree angle to the workpiece directing the filler metal straight into the joint but dont forget to include your travel angle of 5 to 15 degrees. This is popular with flat horizontal and overhead stick welding. With flux-coated welding techniques the dragging approach accelerates the slag to form and stiffen at the back of your puddle as you continue the welding process.

Vertical 7018 welding can benefit from using a weave type pattern. 7 rows With a MIG welder you can weld in the vertical position if you use the common short-circuit.

Solid Wire Vertical Up Miller Welding Discussion Forums

Best Mig Welding Techniques For Everyone

Vertical Uphill Welding Technique

Welding Vertically Mig Welding Forum

Mig Welding Outside Corner Uphill Downhill Youtube

Welding Patterns Welding Projects Welding Table Types Of Welding

0 komentar

Posting Komentar